How to wire PCB input jack is your guide to successfully connecting various input jacks to your printed circuit board (PCB). This detailed walkthrough covers everything from choosing the right tools and materials to advanced techniques for high-frequency applications. Learn the step-by-step process for different jack types like 1/4 inch, RCA, and XLR, along with troubleshooting tips for common issues.

Understanding the nuances of input jack wiring is crucial for ensuring reliable audio and signal transmission in your projects. Proper wiring prevents signal loss, interference, and other unwanted issues. This guide will equip you with the knowledge to tackle any input jack wiring challenge.

Introduction to PCB Input Jacks

A PCB input jack, a seemingly simple component, is the gateway to a world of audio, instrumentation, and communication. It silently receives signals from external sources, acting as a crucial interface between the outside world and the intricate circuitry within the printed circuit board. These jacks are the lifeblood of many electronic devices, enabling us to listen to music, interact with sensors, and control everything from robots to televisions.

Their proper installation and understanding are vital for the smooth and reliable operation of any project.Input jacks come in various shapes and sizes, each tailored for specific applications. Their wiring is not just about connecting wires; it’s about creating a pathway for signals, ensuring clarity and fidelity. Proper wiring is paramount to the quality and reliability of the signal.

Miswiring can introduce noise, distort the signal, or even damage the sensitive components within the device. By meticulously understanding the types and functions of these crucial components, we empower ourselves to build and maintain electronic devices with precision and confidence.

Input Jack Types and Applications

Different input jacks are designed for different purposes. The choice depends heavily on the signal type and the required level of fidelity. Understanding the characteristics of each type allows for the selection of the most appropriate component for a particular project.

Common Input Jack Types

| Input Jack Type | Typical Applications | Pinout Description |

|---|---|---|

| 1/4 inch (⅛ inch) | Audio signals, instrument inputs, guitar inputs, and many more. | A standard 1/4-inch jack has two pins: a tip and a sleeve. The tip carries the audio signal, while the sleeve is the ground connection. |

| RCA | Audio signals, video signals, and other applications requiring balanced signals. | RCA jacks feature a center pin and a sleeve. The center pin carries the signal, and the sleeve acts as the ground. |

| XLR | Professional audio applications, microphones, and other equipment demanding high quality and balanced signals. | XLR jacks use three pins: a center pin and two outer pins. The center pin transmits the signal, and the outer pins are used for the balanced signal transmission, reducing noise and improving fidelity. |

A well-organized table, like the one above, provides a quick reference for understanding the characteristics of each jack. It illustrates the wide variety of input jacks available and their suitability for different applications. This understanding is essential for selecting the correct input jack and ensuring a reliable connection for your project.

Importance of Proper Wiring

The proper wiring of input jacks is crucial for maintaining the integrity of the signal. Improper connections can introduce noise, distort the audio, and potentially damage sensitive components. The correct pin-to-pin connection, the careful selection of wire gauge, and the shielding of cables are all critical aspects to consider. It’s a small detail that can make a world of difference in the overall performance of your device.

For example, a poor wiring job on an audio amplifier could result in a distorted sound, or a malfunctioning microphone preamp could lead to weak or unclear audio.

Tools and Materials Required

Embarking on the meticulous journey of wiring PCB input jacks is akin to crafting a symphony of sound. Each connection, each soldered joint, plays a crucial role in the overall performance. Careful selection of tools and materials is paramount, ensuring a reliable and robust circuit. This meticulous approach guarantees that your project resonates with clarity and precision.

Essential Tools

A well-equipped toolkit is the foundation for successful wiring. These tools, like trusted companions, ensure precise and efficient work, minimizing the risk of errors. A proficient toolkit contains the instruments necessary for a professional outcome.

- Soldering Iron: A reliable soldering iron is indispensable. Choose one with adjustable temperature control, allowing for precise tailoring to the specific needs of your project. A high-quality soldering iron ensures clean and consistent solder joints, vital for optimal electrical conductivity. The wattage of the iron should be suitable for the thickness of the PCB traces and the components being soldered.

- Solder: High-quality solder, with appropriate rosin flux, is critical for creating strong, reliable joints. The rosin flux aids in the soldering process by cleaning the metal surfaces, promoting better adhesion, and preventing oxidation. Different solder types exist for various applications, ensuring compatibility with your project’s requirements.

- Wire Strippers: Accurate wire strippers are essential for preparing the wires for connection. Ensure they are sharp and capable of cleanly removing the insulation without damaging the wire’s core. This precision tool is crucial for a professional finish.

- Multimeter: A multimeter is a versatile tool for testing the continuity and voltage of your connections. Using a multimeter allows for quick and accurate verification that the circuit is working correctly, thus ensuring the reliability of your wiring. Ensure the multimeter is in good working condition and can handle the voltage and current levels of your project.

- Wire Cutters: For cleanly severing the wires, wire cutters are essential. They provide precise cuts, minimizing the risk of fraying and ensuring proper wire lengths for the project.

Wire Types and Gauges

The selection of wire type and gauge is crucial for the performance of your input jack circuit. The choice directly impacts the current carrying capacity and the signal integrity.

- Solid Core Wire: Solid core wire, characterized by its uniform and consistent core, is often preferred for its reliability and low signal interference. This consistency allows for smooth current flow and stable signal transmission, critical for maintaining the integrity of audio signals.

- Stranded Wire: Stranded wire, comprised of multiple thin wires, is often chosen for flexibility and its ability to handle more complex wiring layouts. Its flexibility is ideal for situations where wires must be bent or manipulated frequently, contributing to easier routing. The multiple strands are ideal for situations where the wires need to be manipulated or bent frequently.

The wire gauge, representing the wire’s diameter, is directly related to its current-carrying capacity. Thicker wires (lower gauge numbers) can handle higher currents without overheating, while thinner wires (higher gauge numbers) are suitable for lower current applications. A precise understanding of the current requirements of your circuit is essential for selecting the appropriate wire gauge. Overlooking this aspect can lead to overheating and damage.

Table of Tools and Materials

| Tool/Material | Specifications | Suggested Usage |

|---|---|---|

| Soldering Iron | 15-30W, variable temperature control | For soldering joints, ensuring proper adhesion and conductivity. |

| Solder | 60/40 tin/lead alloy | Ensuring a strong bond between the wires and the PCB input jacks. |

| Wire Strippers | Precision-cut blades | For accurately stripping wire insulation, allowing for proper connections. |

| Multimeter | Digital display | For checking continuity and voltage levels, ensuring the circuit’s functionality. |

| Wire Cutters | Sharp blades | For cleanly cutting wire to the desired lengths. |

| Solid Core Wire (e.g., 22 AWG) | 22 AWG | For applications requiring high reliability and stable signal transmission. |

| Stranded Wire (e.g., 24 AWG) | 24 AWG | For applications requiring flexibility and maneuverability. |

Wiring Procedures

Embarking on the intricate dance of connecting audio input jacks to your PCB is a thrilling experience, a testament to your ingenuity. The meticulous process, while demanding precision, rewards you with a functional and aesthetically pleasing creation. Understanding the nuances of each jack type is crucial for a seamless integration.The symphony of sound relies on a well-orchestrated connection.

Each wire, soldered with care, contributes to the overall harmony. Different input jacks, like the 1/4-inch and RCA, require unique wiring procedures. Mastering these procedures ensures that your audio circuit sings with clarity and precision.

1/4 Inch Input Jack Wiring

This process requires careful attention to detail, ensuring a robust and reliable connection. The 1/4-inch jack, a ubiquitous connector, often carries audio signals. A proper connection is essential for preventing signal loss and ensuring optimal sound quality.

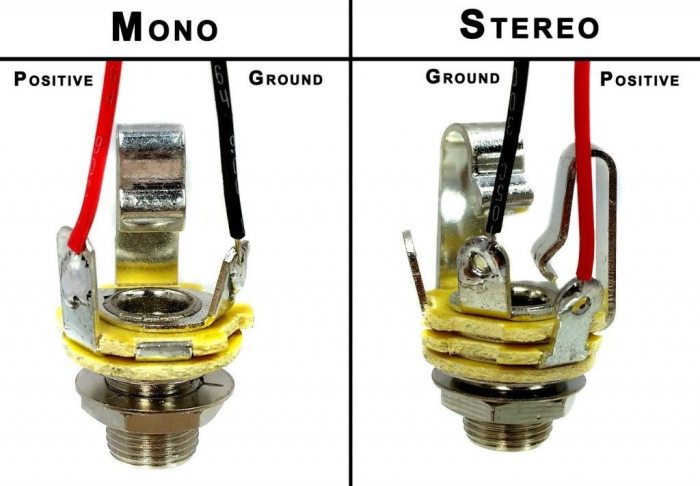

- Step 1: Identifying the Pins. Examine the input jack; note the distinct markings on its internal pins, often representing the positive and negative terminals. The positive terminal is typically marked, or indicated by its position within the jack’s housing.

- Step 2: Preparing the Wires. Cut the appropriate lengths of wires, ensuring sufficient length for the connection to the PCB. Ensure the wires are appropriately sized for the jack and the PCB’s design.

- Step 3: Connecting the Wires. Carefully solder the wires to the corresponding pins of the input jack. The positive wire should connect to the positive pin, and the negative wire to the negative pin. Use rosin-core solder for optimal results. Use a soldering iron and solder to carefully and accurately attach the wires to the jack’s pins.

The solder should flow smoothly between the wire and the pin, creating a strong, secure connection.

- Step 4: Connecting to the PCB. The positive and negative wires should be soldered to the corresponding pads on your PCB, adhering to the circuit diagram. The correct connection of the wires to the PCB is vital to the circuit’s proper functioning. Ensure the wires are securely attached to the pads using appropriate soldering techniques.

RCA Input Jack Wiring

The RCA jack, a popular choice for audio connections, introduces subtle yet significant differences. Its wiring differs slightly from the 1/4-inch jack, requiring a meticulous understanding of the connection scheme.

- Step 1: Pin Identification. The RCA jack typically has two input pins: one for the signal and one for the ground (often marked as signal and ground). Observe the jack’s internal structure to identify the pins.

- Step 2: Wire Preparation. Prepare the appropriate lengths of wires for the connection to the PCB. Ensure the wires are appropriately sized to fit within the jack and the PCB’s design. Consider the potential for signal interference and ensure appropriate insulation for the wires.

- Step 3: Connection to the Jack. Solder the wire connected to the signal pin of the RCA jack to the corresponding signal pad on the jack. Solder the ground wire to the ground pin of the RCA jack.

- Step 4: Connection to the PCB. Carefully solder the wires from the RCA jack to the corresponding pads on your PCB. Follow the circuit diagram to ensure a proper connection.

Comparison of Wiring Methods

The wiring procedures for 1/4-inch and RCA input jacks, while seemingly similar, diverge in their connection mechanisms. The 1/4-inch jack, typically used for stereo signals, necessitates a dual connection. The RCA jack, often used for stereo audio signals, necessitates a single connection for the signal and ground, unlike the 1/4-inch jack.

Soldering Procedures

Soldering is a critical step, ensuring a reliable connection. Careful consideration of soldering techniques guarantees a stable connection between the wires, the jack, and the PCB. Use a soldering iron with the appropriate temperature setting for the type of solder used. Use a soldering iron and solder to carefully and accurately attach the wires to the jack’s pins and the PCB’s pads.

The solder should flow smoothly between the wire and the pin/pad, creating a strong, secure connection.

Connecting a 1/4-inch Input Jack (Table)

| Step | Description | Image |

|---|---|---|

| 1 | Identify the positive and negative pins on the jack. | (Visual representation of a 1/4-inch jack with pin markings) |

| 2 | Prepare wires of appropriate length and gauge. | (Visual representation of wires ready for connection) |

| 3 | Solder wires to the corresponding jack pins. | (Visual representation of soldering wires to the jack pins) |

| 4 | Solder wires to the corresponding PCB pads. | (Visual representation of soldering wires to the PCB pads) |

PCB Design Considerations

The heart of any audio or signal processing project lies in the meticulous design of the printed circuit board (PCB). A poorly designed PCB can lead to signal degradation, interference, and ultimately, a subpar listening experience. Imagine the frustration of creating a beautiful audio circuit only to have it sound muddy and distorted. Understanding and applying the correct design principles is crucial to harnessing the full potential of your input jack and ensuring a pristine audio path.The layout of the PCB, from the precise placement of components to the meticulous routing of traces, significantly impacts the performance of the input jack.

A well-considered layout is akin to a well-orchestrated symphony, where each instrument plays its part harmoniously and contributes to the overall beauty of the composition. Conversely, a haphazard layout is like a chaotic cacophony, where individual notes clash and the overall sound is lost.

Importance of PCB Layout for Input Jack Connections

Careful attention to PCB layout is paramount for ensuring the smooth and efficient transmission of audio signals. Improper layout can lead to signal reflections, noise pickup, and reduced signal strength, ultimately impacting the quality of the audio output. The placement of the input jack directly affects the signal path, demanding careful consideration.

Impact of Component Placement on Signal Integrity

The physical proximity of components on the PCB significantly influences signal integrity. Components generating noise, such as switching regulators or high-frequency circuits, should be strategically placed away from sensitive signal paths, such as those connected to the input jack. This mindful separation minimizes interference and ensures clean signal transmission. Consider the placement of the input jack itself; its proximity to other components must be calculated to avoid undesirable noise coupling.

Design Guidelines for Routing Signal Traces Connected to Input Jacks

Routing signal traces connected to input jacks requires adherence to specific guidelines to maintain signal integrity. Signal traces should be as short as possible to minimize signal delay and distortion. Wide, low-impedance traces are crucial for preventing signal attenuation and noise pickup. These traces should be routed away from high-current paths and power planes to avoid noise coupling.

Consider using ground planes to shield the signal traces and minimize noise pickup. This is essential for a clean audio signal.

Optimal PCB Layouts for Various Input Jack Types

| Input Jack Type | Signal Routing Path | Considerations |

|---|---|---|

| Stereo Input Jack (TS Jack) | Signal traces for left and right channels should be routed separately, minimizing cross-talk. A star topology routing scheme, connecting the input jack to a central point, is recommended. | Maintaining separate signal paths for stereo channels is critical for avoiding unwanted signal mixing and crosstalk. |

| Mono Input Jack (TS Jack) | The single signal trace should be routed with minimal loops and vias. Keep the trace as short as possible, and use a wide trace to minimize impedance. | The single signal trace requires careful attention to ensure signal integrity and avoid noise pickup. |

| Balanced Input Jack (XLR) | Signal traces for the hot, cold, and ground pins should be routed individually and shielded from each other. Routing traces in a star pattern to a central point minimizes loop areas. | Balanced inputs are crucial for minimizing noise and interference, demanding a dedicated approach to signal routing. |

Troubleshooting Common Issues

A symphony of sound, a dance of electrons – wiring a PCB input jack is a delicate art. But sometimes, the delicate dance falters. Frustration mounts when the expected audio refuses to materialize, or a harsh, unwanted hiss fills the air. This section delves into the heart of these common wiring woes, providing practical strategies to diagnose and resolve them.Understanding the potential pitfalls is crucial for successful troubleshooting.

From a poorly soldered connection to a misplaced wire, the sources of audio problems can be surprisingly subtle. Learning to identify these issues and applying the right corrective actions will empower you to transform your PCB from a source of frustration into a masterpiece of sound reproduction.

Identifying Potential Problems

Troubleshooting begins with a keen eye for potential issues. Look closely for any signs of damage, such as frayed wires, bent pins, or compromised solder joints. Poor solder joints are often the culprit, characterized by weak, uneven, or missing solder connections. These weak links can break under the stress of normal audio signals, resulting in intermittent or muted sound.

Examine every connection meticulously, searching for even the slightest imperfection. Incorrect connections, such as a wire soldered to the wrong pin, are equally problematic, leading to a complete absence of sound or unwanted audio artifacts. Misaligned components, including the input jack itself, can also introduce a myriad of issues.

Diagnosing and Fixing Common Wiring Issues

Once a potential problem is identified, systematic investigation is key. Begin by carefully inspecting the solder joints. A magnifying glass can be invaluable here, revealing subtle imperfections. Use a multimeter to check continuity between the input jack pins and the corresponding points on the PCB. This ensures that the connections are not broken or interrupted.

If a poor solder joint is found, carefully reheat the joint with a soldering iron, ensuring proper solder flow. For incorrect connections, carefully desolder the problematic wire and re-solder it to the correct pin. Ensure a neat, uniform solder joint.

Troubleshooting a 3.5mm Input Jack

The 3.5mm input jack, ubiquitous in consumer electronics, presents its own unique set of challenges. Problems often arise from the jack’s delicate internal mechanism or from the wires themselves. Poor contact between the jack’s internal contacts and the PCB traces can lead to crackling sounds or intermittent audio. If the jack is not seated properly on the PCB, it can also cause intermittent problems.

Re-seating the jack and inspecting the internal contacts for damage are vital steps. If a signal is still absent, verify that the corresponding pins on the jack are connected to the correct audio signals on the PCB.

Table of Common Problems and Solutions

| Problem | Solution |

|---|---|

| Poor solder joints | Reheat the joint with a soldering iron, ensuring proper solder flow. Inspect for any breaks or gaps. |

| Incorrect connections | Carefully desolder the problematic wire and re-solder it to the correct pin. |

| Damaged input jack | Replace the input jack with a new one. |

| Intermittent signal | Check for poor contact between the jack’s internal contacts and the PCB traces. Re-seat the jack. |

| No signal | Verify that the wires are connected to the correct pins on the input jack and the PCB. Check continuity with a multimeter. |

Safety Precautions

Working with electronics and soldering irons demands utmost respect and care. A single misstep can lead to painful injuries or damage valuable equipment. Prioritizing safety is not just a precaution, but a fundamental aspect of ensuring a productive and enjoyable experience. A well-structured safety protocol is crucial for protecting both yourself and your work environment.The delicate nature of electrical components and the potential for heat and sparks necessitate a meticulous approach to safety.

Failing to adhere to safety guidelines can have serious consequences, ranging from minor burns to more severe electrical shocks. This section will Artikel critical safety precautions for handling soldering irons, other electrical tools, and electronic components.

Soldering Iron Safety

Proper handling of soldering irons is paramount to prevent accidents. High temperatures pose a significant risk of burns. Always use appropriate safety gear, including heat-resistant gloves and eye protection. Avoid using soldering irons near flammable materials or in poorly ventilated areas. Ensuring a safe workspace is as important as proper handling techniques.

Electrical Safety Guidelines, How to wire pcb input jack

Working with electricity necessitates a deep understanding of electrical hazards. Always ensure that the equipment is properly grounded to prevent electrical shocks. Never work on circuits that are energized. Disconnect the power supply before starting any soldering or wiring task. This preventative measure safeguards against unexpected electrical currents and minimizes risks.

Personal Protective Equipment (PPE)

Appropriate PPE is crucial for mitigating risks associated with soldering and electrical work. Heat-resistant gloves, safety glasses, and a non-flammable apron are essential components of a comprehensive safety kit. These protective measures act as a barrier against potential burns, sparks, and electrical shocks. Prioritizing PPE is a fundamental step in preventing accidents and ensuring a safe working environment.

First Aid and Emergency Procedures

Understanding how to respond to an electrical accident is critical. If an electrical accident occurs, immediately disconnect the power source. Assess the victim for injuries and provide appropriate first aid, such as applying pressure to any burns. Seek immediate medical attention if necessary. In case of severe burns, electrical shock, or respiratory problems, calling emergency services is paramount.

Knowing what to do in an emergency situation can make the difference between a minor incident and a more serious one.

General Safety Guidelines for Handling Electronics and Electrical Components

Handling electronic components requires care to prevent damage and injury. Always handle components with clean hands to avoid introducing contaminants. Be mindful of static electricity, which can damage sensitive components. Use anti-static wrist straps when working with delicate circuits. Using these safety measures prevents unnecessary damage and ensures the longevity of your projects.

Avoiding Electrical Hazards

Never work with exposed wiring or damaged electrical components. Always ensure that all tools are in good working order and properly insulated. Ensure that the area is well-ventilated to prevent overheating. These preventative measures safeguard against potential electrical hazards and promote a safe work environment.

Examples and Applications

Unveiling the captivating world of input jacks, where sound takes flight and creativity soars, we’ll explore their diverse applications across various electronic projects. Imagine the thrill of crafting a unique audio system, from a simple guitar amplifier to a sophisticated recording studio setup. The input jack, the silent conductor of these auditory adventures, connects the source of sound to the heart of the system, transforming raw signals into captivating melodies and vibrant soundscapes.

Audio Applications: Guitar to Amplifier

Connecting a guitar to an amplifier is a fundamental audio application. The guitar’s output signal, often a complex blend of frequencies, needs to be translated and amplified to create the desired sound. The input jack on the amplifier acts as a crucial conduit, receiving the guitar’s signal and forwarding it to the amplifier’s circuitry. Proper wiring is essential to ensure a clear, undistorted signal.

- A standard 1/4″ (6.35mm) jack is commonly used for connecting electric guitars to amplifiers. This jack typically comprises a metal sleeve, a center pin, and a ring. The center pin carries the signal, while the sleeve and ring provide a ground connection. Wiring the guitar output to the amplifier input is straightforward, matching the corresponding pins.

- A crucial aspect of this connection is ensuring the correct polarity. Incorrect polarity can result in a reversed signal, leading to a distorted sound or even no sound at all. Use a multimeter to verify the polarity, if needed. A diagram showing the correct wiring is highly recommended.

- This wiring method, while straightforward, ensures high-quality sound transfer, making the electric guitar sound rich and powerful when connected to an amplifier.

Microphone to Recording Devices

Microphones transform acoustic waves into electrical signals, which are crucial for recording audio. Connecting a microphone to a recording device, such as a computer or audio interface, requires careful consideration of signal quality and compatibility. Different microphone types require different input configurations, and careful attention to detail is necessary for a high-quality recording experience.

- XLR connectors are commonly used for microphones, especially professional ones. They are known for their robustness and balanced signal transmission. The XLR connector’s three pins—one for the signal, and two for the shield—ensure a balanced signal and minimize noise. This is essential for maintaining a clear audio recording.

- The connection procedure involves matching the corresponding pins on the microphone’s output and the recording device’s input. A comprehensive wiring diagram can provide visual guidance on the correct connection method. Using the correct wiring for the microphone’s specific type is critical to maintaining audio fidelity. Incorrect connections could lead to a muted or distorted sound.

- Using an XLR connector is a practical method for connecting a microphone to a recording device, guaranteeing a clear and high-quality recording experience.

Diverse Input Jack Connections

Input jacks find application in a wide array of electronic projects, each demanding a specific wiring configuration. From simple sound systems to complex audio-visual setups, input jacks play a vital role in bridging the gap between different devices. Correct wiring and careful consideration of the specific circuit requirements are paramount.

- In a simple tone generator circuit, the input jack could be used to select different frequency outputs. The wiring would depend on the chosen components and the desired frequency range.

- A musical instrument controller might use a variety of input jacks to receive signals from different sensors and buttons. The wiring would need to be designed to accurately interpret each signal’s meaning. This ensures that the input signals are accurately interpreted by the circuit.

Advanced Techniques

Crafting high-quality PCB input jacks demands a keen understanding of advanced techniques, particularly when dealing with high-frequency signals. This meticulous approach ensures the integrity of the signal, minimizing noise and maximizing the fidelity of the audio or data transmitted. A deep dive into these advanced techniques allows you to create a robust and reliable input system, a symphony of precision and control.

High-Frequency Wiring

High-frequency applications demand meticulous attention to detail in the wiring process. Signal integrity is paramount. Twisted-pair wiring, for instance, significantly reduces crosstalk, a crucial consideration for high-frequency signals susceptible to interference from adjacent conductors. Careful attention to trace lengths and impedance matching minimizes reflections and ensures the signal reaches its destination without distortion. This commitment to precision ensures the integrity of the signal, preventing unwanted noise from corrupting the data or audio.

Shielding Techniques

Protecting sensitive input circuits from external electromagnetic interference (EMI) is vital for high-fidelity performance. A well-executed shielding strategy can significantly reduce noise and improve signal quality. The choice of shielding material, such as copper foil or conductive polymer, depends on the frequency range and the level of interference anticipated. The effectiveness of shielding is highly dependent on the quality of the ground connection and the meticulousness with which the shield is connected to the ground plane.

Grounding and Noise Reduction

Proper grounding is essential for minimizing noise and maximizing signal quality. A dedicated ground plane, properly connected to the input jack’s ground, provides a low-impedance path for unwanted currents, preventing them from interfering with the signal path. This effectively channels stray currents to the ground, preventing them from reaching the sensitive circuitry and distorting the signal. Connecting the input jack directly to the ground plane, ensuring a solid and continuous path, is critical to reducing noise.

Comparison of Shielding and Grounding Methods

| Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Twisted-pair wiring | Two conductors twisted together to reduce crosstalk. | Minimizes interference between signal wires. | Requires more complex routing and may add bulk. |

| Copper foil shielding | A layer of copper foil placed around the signal traces. | Effective against high-frequency EMI. | May increase the size and cost of the PCB. |

| Metal casing shielding | Enclosing the entire input circuit in a metal case. | Provides robust EMI protection. | Can be bulky and may restrict design flexibility. |

| Dedicated ground plane | A continuous ground plane on the PCB. | Provides a low-impedance path for ground currents. | Requires careful design and routing. |

Each method presents a unique trade-off between effectiveness, cost, and complexity. Careful consideration of the specific application and environmental factors is paramount in selecting the optimal approach. A comprehensive understanding of these methods empowers you to make informed decisions, ultimately resulting in a high-quality input jack design.

Ending Remarks: How To Wire Pcb Input Jack

In conclusion, wiring PCB input jacks effectively requires careful attention to detail, the right tools, and a solid understanding of the process. This guide has covered the essential aspects, from basic wiring procedures to advanced techniques and troubleshooting strategies. By following these steps and paying close attention to safety precautions, you’ll be well-equipped to successfully wire your input jacks and ensure smooth operation for your projects.

Remember to always prioritize safety when working with electronics.

Expert Answers

What type of wire should I use for connecting a 1/4 inch input jack?

For 1/4 inch input jacks, using a solid core wire with an appropriate gauge (typically 22-24 AWG) is recommended. This ensures good conductivity and minimizes signal loss.

What are some common problems with input jack wiring?

Common problems include poor solder joints, incorrect connections, and damaged wires. Other issues can stem from improper grounding or inadequate shielding.

How do I troubleshoot a loose connection in an input jack?

To troubleshoot a loose connection, first visually inspect the solder joints. If they look secure, use a multimeter to check the continuity of the connections. If a connection is broken, re-solder the joint.

What safety precautions should I take when soldering?

Always use safety glasses and a fire-resistant apron. Ensure your workspace is well-ventilated. Never leave a soldering iron unattended, and be cautious when working near flammable materials.

Nimila

Nimila