How to install throttle position sensor? This isn’t just about replacing a part; it’s about understanding the heart of your car’s engine. Imagine a tiny, yet crucial, conductor orchestrating the symphony of your vehicle’s power. That’s the throttle position sensor (TPS). A faulty TPS can lead to a frustratingly bumpy ride, a sputtering engine, and a whole lot of headaches.

This guide breaks down the process step-by-step, from diagnosing the problem to the final, satisfying whir of a perfectly tuned engine.

This comprehensive guide will walk you through the process of replacing a throttle position sensor (TPS), a crucial component in any vehicle’s engine management system. We’ll cover everything from identifying symptoms of a faulty TPS to performing the actual installation, ensuring a smooth and efficient repair. Get ready to become a master mechanic, one TPS at a time.

Introduction to Throttle Position Sensor (TPS)

Yo, so you wanna know about the TPS? It’s like the engine’s translator, telling the computer exactly how much gas to give. Crucial for smooth running, from idling to full throttle. Without a good TPS, your ride’ll be a bumpy mess.The Throttle Position Sensor (TPS) is a vital component in a vehicle’s engine management system. Its job is to measure the position of the throttle plate.

This measurement is sent to the engine control unit (ECU), which then adjusts the fuel and air mixture accordingly, controlling the engine’s power output. Think of it as the engine’s way of knowing how hard you’re pushing the gas pedal.

Signs of a Faulty TPS, How to install throttle position sensor

Problems with the TPS can manifest in various ways. Common symptoms include engine misfires, making it cough and sputter. You might also experience rough idling, like the engine’s struggling to stay at a steady speed. Acceleration problems, where the car feels sluggish or hesitant to respond to the gas pedal, are another telltale sign. These issues can vary in severity, but they all point to a potential TPS problem.

TPS Location on a Common Engine Type

Imagine a typical inline-4 engine. The TPS is usually located near the throttle body, often mounted on the throttle body itself or on a bracket nearby. It’s connected to the throttle plate via a cable or a direct linkage, and the signal wire runs to the ECU. Visualizing this will help you understand its role in the engine’s operation.

Different TPS Types

Understanding the different types of TPS is crucial for proper diagnosis and replacement. Each type has its own operating principle and characteristics.

| Type | Operating Principle | Advantages | Disadvantages |

|---|---|---|---|

| Resistive | Changes in resistance based on throttle position. | Relatively inexpensive. | Susceptible to wear and tear, less precise. |

| Hall Effect | Uses a magnetic field to detect the throttle position. | More precise, durable. | Generally more expensive. |

Choosing the right TPS type depends on the specific vehicle and its needs. Some cars might require a precise hall effect sensor, while others may function well with a resistive one. This knowledge will be useful when troubleshooting problems and performing maintenance.

Tools and Materials Needed

Woy, siap-siap nih buat ganti TPS! Ini nih, list alat dan barang yang perlu lo siapkan biar prosesnya lancar dan aman. Jangan sampe salah satu itemnya ketinggalan, ya!Ganti TPS emang nggak ribet banget, tapi perlu ketelitian dan alat yang tepat. Ini penting banget buat memastikan hasil kerjaan rapi dan nggak ada masalah di jalan. Kita bahas detailnya, yuk!

Required Tools

Ini dia alat-alat yang wajib lo punya buat bongkar pasang TPS. Jangan sampe salah pilih, ya! Pilih yang sesuai sama jenis mobil lo, biar aman.

- Kunci pas set: Penting banget buat lepas baut-baut di sekitar TPS. Pastikan ukurannya sesuai sama baut yang ada di mobil lo. Kalo salah ukuran, bisa bermasalah.

- Set kunci ring/socket: Sama pentingnya buat lepas baut yang agak susah dijangkau. Jangan lupa bawa kunci pas yang pas ukurannya ya!

- Obeng: Buat beberapa baut dan sekrup kecil. Pastikan obengnya dalam kondisi baik dan nggak bengkok.

- Multimeter: Penting banget buat ngecek kondisi TPS yang baru dan yang lama. Ini bisa ngasih tahu apakah TPS nya masih bagus atau udah rusak.

- Tang kombinasi: Buat bantuin ngelepas kabel atau komponen lainnya. Penting banget buat keselamatan.

- Tang lancip: Buat bantuin ngelepas kabel atau komponen lainnya yang susah dijangkau. Sama pentingnya buat keselamatan.

- Kunci pas khusus: Kalo mobil lo butuh kunci pas khusus, siapkan juga, ya. Pastikan ukurannya sesuai dengan kebutuhan mobil lo.

Required Parts

Nah, ini bagian barang-barang yang perlu lo beli. Jangan lupa cek dulu spesifikasi mobil lo biar pas sama TPS yang baru.

- Throttle Position Sensor (TPS) baru: Ini yang paling penting! Pastikan TPS yang lo beli sesuai dengan spesifikasi mobil lo. Salah satu, bisa bikin masalah.

- Kabel dan konektor (jika diperlukan): Pastikan kabel dan konektor yang lo beli sesuai dengan kabel dan konektor yang lama. Kalau salah, bisa bermasalah.

- Vaseline atau grease (opsional): Buat bantuin pastiin sambungan kabel dan konektor aman dan nggak ada masalah. Buat jaga-jaga aja, ya.

Safety Precautions

- Matikan mesin dan cabut aki: Ini langkah paling penting untuk menghindari sengatan listrik. Jangan asal-asalan, ya!

- Kenakan sarung tangan dan kacamata pelindung: Ini buat menjaga tangan dan mata lo dari benda-benda tajam atau kotoran yang mungkin ada.

- Pastikan area kerja rapi dan terhindar dari halangan: Buat menghindari kecelakaan atau kerusakan pada komponen lain di sekitar TPS.

- Periksa kondisi TPS lama sebelum bongkar: Buat tahu kondisi TPS lama dan memastikan TPS baru yang dibeli sesuai.

Table of Tools and Parts

| Tool Type | Description | Part Type | Description |

|---|---|---|---|

| Kunci Pas Set | Berbagai ukuran kunci pas untuk baut-baut TPS | TPS Baru | TPS yang sesuai dengan spesifikasi mobil |

| Kunci Ring/Socket Set | Berbagai ukuran kunci ring/socket untuk baut-baut TPS | Kabel dan Konektor | Kabel dan konektor yang sesuai |

| Obeng | Berbagai ukuran obeng untuk sekrup-sekrup TPS | Vaseline/Grease (Opsional) | Untuk melindungi sambungan kabel |

| Multimeter | Untuk mengecek kondisi TPS | – | – |

Vehicle-Specific Procedures

Gak usah ribet, gan. Pasang sensor TPS ini penting banget, soalnya langsung ngaruh ke kinerja mesin. Tapi, jangan asal ngoplak aja, ya. Setiap mobil beda-beda, jadi harus ikuti petunjuknya yang spesifik. Penting banget, nih!

General TPS Replacement Procedure

Untuk ganti TPS, penting banget ikuti petunjuk bengkel atau manual buku panduan mobil lo. Jangan asal ngikutin tutorial yang cuma nge-share di internet, karena bisa salah. Beda tipe mobil, beda juga caranya. Pastiin lo ngerti dan teliti banget, supaya nggak salah langkah.

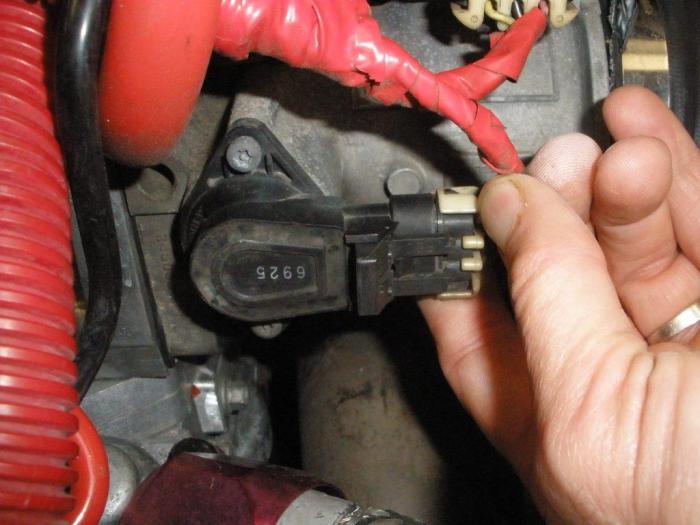

Disconnecting the TPS Connector

Sebelum bongkar TPS lama, penting banget putuskan sambungan konektornya. Biasanya ada konektor khusus yang harus dilepas. Periksa dulu konektornya, jangan sampai kabelnya copot. Pastikan kabelnya terhubung dengan aman ke konektornya. Jangan dipaksa, ya!

- Cari konektor TPS di bawah kap mobil.

- Lepaskan konektor dengan hati-hati, jangan sampai kabelnya putus.

- Catat posisi kabelnya, biar pas pasang balik.

Removing the Old TPS Sensor

Setelah konektor lepas, tinggal bongkar sensor TPS lama. Prosesnya beda-beda di setiap mobil. Pastikan lo ngerti caranya dan hati-hati banget, jangan sampai ngerusak bagian lain.

- Cari baut-baut yang nyangkut di TPS. Lepasin semua bautnya.

- Lepasin selang-selang atau kabel yang nyambung ke TPS.

- Gunakan kunci pas yang tepat untuk lepas sensor TPS lama.

- Bongkar sensor TPS lama dengan hati-hati, jangan sampai bagian lain rusak.

Installing the New TPS Sensor

Pasang sensor TPS baru dengan teliti. Pastikan posisi sensor pas dan nggak ada yang salah. Jangan sampai ada kabel yang nyangkut atau posisi sensor nggak tepat.

- Pasang sensor TPS baru ke tempatnya.

- Pastikan semua kabel terhubung dengan benar.

- Pasang kembali baut-baut yang sudah dilepas.

- Kencangkan baut-bautnya dengan pas, jangan terlalu kencang atau terlalu longgar.

Verifying TPS Wiring and Connections

Setelah pasang sensor TPS baru, cek lagi kabel-kabelnya. Pastikan semua konektor terpasang dengan benar dan nggak ada yang salah. Cek lagi, ya, jangan sampai ada kesalahan.

- Pastikan semua kabel terhubung dengan benar ke konektor.

- Periksa kembali posisi konektor dan kabelnya.

- Cek lagi dengan manual buku panduan mobil lo.

Comparison of TPS Replacement Procedures (Examples)

Contoh, mobil Honda Civic beda caranya sama mobil Toyota Camry. Setiap merk mobil punya cara sendiri. Periksa manual buku panduan mobil lo, ya.

| Merk Mobil | Perbedaan Prosedur |

|---|---|

| Honda Civic | Biasanya butuh kunci khusus untuk lepas sensor TPS. |

| Toyota Camry | Posisi kabelnya lebih rumit. |

| Mitsubishi Lancer | Perlu diperhatikan posisi sensor dan kabelnya. |

Diagnosing the Problem

Nah, masalah TPS nih kadang bikin pusing. Gak langsung keliatan, kadang suka ngelunjak, bikin mesin berisik, atau malah ga mau nyala. Jadi, kita perlu cek dulu, jangan asal ganti part. Ini panduan troubleshooting buat TPS yang bermasalah.

Troubleshooting a Faulty TPS

Untuk ngecek TPS yang bermasalah, kita perlu sistematis. Jangan asal bongkar pasang, bisa-bisa makin ribet. Kita harus identifikasi kemungkinan penyebabnya, mulai dari kabel yang bermasalah, sampai sensornya sendiri yang lemot.

Potential Causes of a Faulty TPS

Beberapa hal yang bisa bikin TPS bermasalah, antara lain:

- Wiring Issues: Kabel yang putus, kendor, atau terkelupas bisa bikin sinyal ke ECU ga nyampe. Bayangin aja, kayak sinyal telepon yang ga sampai ke tujuan, ya pasti masalah. Ini harus dicek satu-satu, kabelnya di cek, sambungannya di cek.

- Electrical Problems: Bisa juga ada masalah di sistem kelistrikan mobil, misalnya arus pendek atau ground yang ga stabil. Ini bisa bikin TPS ga bisa bekerja dengan benar. Seperti lampu yang ga mau nyala, itu bisa jadi masalah arus listrik.

- Sensor Malfunction: Sensor TPS sendiri bisa rusak karena usia, benturan, atau kotoran. Bayangin aja, sensornya kotor kaya kaca mobil yang berembun, ya pasti ga keliatan. Sensornya perlu dibersihkan, atau mungkin harus diganti.

Using a Multimeter to Test TPS Output

Sekarang, kita masuk ke cara ngecek TPS pake multimeter. Ini penting banget buat memastikan TPS bekerja dengan benar. Multimeter bisa ngukur tegangan yang dihasilin TPS sesuai posisi pedal gas.

Pastikan multimeter kamu udah disetting ke mode DC Voltage.

Cara pemakaiannya, colok probe multimeter ke terminal TPS, lalu injak pedal gas perlahan. Perhatikan angka yang muncul di multimeter.

Expected Voltage Readings

Berikut tabel yang menunjukkan voltage yang seharusnya muncul di TPS pada berbagai posisi pedal gas.

| Throttle Position | Expected Voltage (Volts) |

|---|---|

| Idle (pedal gas santai) | 0.5 – 1.0 |

| Mid-Throttle (pedal gas sedang) | 1.0 – 4.5 |

| Full Throttle (pedal gas penuh) | 4.5 – 5.0 |

Ini cuma perkiraan, bisa beda-beda tergantung tipe mobil dan sensornya. Kalau bacaannya ga sesuai, berarti ada masalah di TPS atau kabelnya.

Wiring Diagrams and Connections

Nah, urusan kabel TPS ini penting banget, gan. Salah nyambung bisa bikin mesin mogok, kayak motor ngadat gara-gara kabel putus. Jadi, pahamin dengan baik ya, biar installasinya lancar.

Wiring Diagram Example (Toyota Camry 2010)

Berikut contoh diagram wiring untuk Toyota Camry 2010. Inget, ini contoh aja, pasti beda-beda tergantung model mobilnya. Penting banget cek diagram mobil lo sendiri!

| Color | Signal | Description |

|---|---|---|

| Red/Black | +12V | Supply voltage from the battery. Pastiin ini terhubung dengan baik, biar TPS bisa jalan. |

| Black | Ground | Ground connection. Penting banget nih, buat nyambungin ke rangka mobil. |

| Purple/Yellow | TPS Signal | Output signal dari TPS, mengindikasikan posisi pedal gas. Ini yang penting banget, buat ngatur berapa banyak bensin yang masuk ke mesin. |

| Green/White | Power to the TPS | Power supply to the TPS. Ini penting buat memastikan TPS berfungsi dengan normal. |

Identifying Correct Connections

Setelah dapet diagramnya, pertama-tama cari terminal TPS di mobil. Biasanya ada label atau kode yang jelas. Pastikan TPS lo pas sama diagram. Kedua, cocokin warna kabel dengan tabel di atas. Ketiga, pastikan setiap kabel terhubung ke terminal yang benar di TPS dan di ECU.

Kalau bingung, lebih baik tanyakan ke mekanik atau cek di forum mobil.

Troubleshooting Wiring Issues

Kalau ada masalah saat nyambungin kabel, cek lagi semua koneksinya. Pastikan semua kabel terhubung dengan baik dan nggak ada yang terputus atau short. Tes TPS dengan alat khusus buat ngecek TPS, kalau ada masalah, cek juga ke ECU, karena bisa jadi ada masalah di sana. Kadang-kadang, masalahnya cuma di kabel yang kendur atau nggak terhubung dengan baik.

Troubleshooting and Common Issues

Nah, installing a TPS ain’t always a walk in the park, ya know? Sometimes, things go sideways. We’ll cover some common snags and how to fix ’em, so you can get that engine purrin’ like a kitten.

Wiring Issues

Wiring problems are a pretty frequent culprit. Incorrect connections or damaged wires can lead to a whole host of issues. Double-check all your connections, making sure everything’s snug and secure. Look for any signs of frayed wires or broken insulation. If you find a problem, replace the wire or connector, and re-install the TPS.

Sensor Misalignment

A misaligned TPS sensor can cause inaccurate readings, making the engine act up. Make sure the sensor is properly seated in its mounting location. Double-check that the mounting bracket is securely attached. If the sensor is loose or shifted, realign it carefully and tighten everything back up.

Damaged Connectors

Sometimes, the problem isn’t with the sensor itself, but with the connectors. Damaged or corroded connectors can lead to erratic readings. Clean the connectors thoroughly with a good contact cleaner. If they’re really messed up, replace the connectors. Make sure you use the correct type of connector for your specific vehicle.

Inaccurate Readings

If the TPS is giving you funky readings, there could be a few reasons. A dirty sensor can cause inaccurate readings. Clean the sensor with a proper cleaning solution and make sure it’s properly connected. Make sure the sensor is not blocked or obstructed by anything. Also, check the wiring connections again.

Bad connections or a faulty ground can mess with the sensor’s readings. If you’ve ruled out those, a faulty sensor itself could be the issue.

Error Codes

Different vehicles use different diagnostic systems. Some common error codes associated with TPS malfunctions include P0120, P0121, P0122, P0123. These codes often point to a problem with the TPS signal. Check your vehicle’s specific diagnostic manual for detailed explanations of these error codes and how to troubleshoot them.

Example of a Common Error Code and Solution (P0121)

Let’s say you get a P0121 error code. This often means there’s a problem with the TPS signal or a problem with the signal being sent to the ECU. First, check the wiring. Double-check the connectors, ensuring they are properly attached and free of corrosion. Next, check the sensor itself.

Is it properly aligned and seated? If the wiring and sensor seem okay, consider a more advanced approach. Consult your vehicle’s repair manual or a qualified mechanic to diagnose further. They might have specific tools or procedures for identifying and resolving the issue.

Verification and Testing: How To Install Throttle Position Sensor

Alright, so you’ve got the new TPS installed. Now, it’s time to make sure everything’s working perfectly, like a brand new motor. We need to verify the installation and make sure the sensor is sending the right signals to the ECU (Engine Control Unit). No point in having a new part if it’s not doing its job, right?

Verifying Proper Installation

First things first, double-check that the TPS is securely mounted. Make sure all the bolts are tight and the sensor is sitting in the right spot, aligned correctly with the throttle plate. If it’s not snug, it won’t give accurate readings, and your car will be acting weird. Double-check the wiring connections too. Loose connections can lead to problems.

Make sure all the electrical connections are secure and properly terminated.

Testing the TPS Output Signal

Now, let’s test the TPS’s output signal. This signal tells the ECU how far the throttle is open. Using a multimeter set to the DC voltage range, you can measure the output voltage of the TPS while the engine is off. The voltage should vary based on the throttle position. The closer to the full throttle position, the higher the voltage.

If the voltage doesn’t change, or it’s way off the expected range, it’s a sign there’s something wrong. A good way to do this is to note the voltage readings at different throttle positions (e.g., 10%, 25%, 50%, 75%, 100% throttle). Compare these readings to the specifications in your vehicle’s repair manual.

Using a Scan Tool

A scan tool is your best friend when diagnosing electronic problems. It can read error codes related to the TPS. Many scan tools have a way to monitor the TPS’s output signal in real-time, letting you see how it responds to throttle input. If the scan tool shows a TPS-related error code, it’ll usually tell you what’s wrong (e.g., “TPS signal out of range”).

This will give you a heads-up about potential problems.

Performing a Road Test

Finally, a road test is crucial. This helps you see how the engine responds to throttle input in real-world conditions. Start the engine and gently accelerate. The engine should respond smoothly without any hesitation or surging. If the engine sputters or doesn’t accelerate properly, it could be a sign that the TPS isn’t working as intended.

Drive around for a bit, checking for any issues with the acceleration or idling speed. Pay attention to any unusual noises or vibrations, too.

Ultimate Conclusion

So, you’ve successfully installed your new throttle position sensor. Now, your engine should respond with newfound precision, providing a smoother, more powerful ride. Remember, proper installation is key, and this guide provided a step-by-step approach to ensure a flawless outcome. If you encounter any unusual issues, always consult your vehicle’s manual or a qualified mechanic. Happy motoring!

Essential FAQs

What are the common symptoms of a faulty TPS?

Symptoms often include rough idling, hesitation during acceleration, inconsistent fuel delivery, and even engine misfires. Pay attention to these subtle clues to pinpoint the problem.

What tools are essential for TPS replacement?

You’ll need a wrench set, socket set, multimeter, and potentially specialized tools depending on your car model. Always prioritize safety, disconnecting the battery before starting.

How do I know if the correct TPS wiring is connected?

Refer to your vehicle’s wiring diagram. Incorrect wiring can lead to serious problems. Carefully match the colors and functions to the diagram to ensure accurate connections.

What if I encounter an error code after installation?

Consult your vehicle’s diagnostic manual or a mechanic. Error codes provide valuable clues about the nature of the issue. Don’t hesitate to seek professional help if needed.

Nimila

Nimila